As demand for outsourced production continues to rise, the role of the contract manufacturing organization (CMO) is more vital and more complex than ever. Whether in pharmaceuticals, consumer goods, or specialty chemicals, CMOs are tasked with producing high-quality products while maintaining flexibility, compliance, and operational excellence.

But scaling operations isn’t just about adding new equipment or expanding facility footprints. Without a robust labor strategy, growth can quickly turn into chaos. Explore how to strategically scale workforce operations within a contract manufacturing organization, the common pitfalls, and how labor management software like Indeavor helps fill the gaps.

What Does a Contract Manufacturing Organization Do?

A contract manufacturing organization is a company hired by another business to produce goods on its behalf. These services often include manufacturing, packaging, labeling, and sometimes even logistics. In the pharmaceutical contract manufacturing space, for example, CMOs handle everything from raw material sourcing to batch production of drugs according to FDA guidelines.

CMOs allow companies to focus on R&D, marketing, or other core functions without having to maintain expensive production infrastructure. In return, CMOs must maintain flexibility across multiple client contracts, often with varying quality standards, delivery schedules, and compliance requirements.

What Is a Contract Manufacturing Corporation?

A contract manufacturing corporation refers to any legally incorporated business that provides contract manufacturing services. While “organization” and “corporation” are often used interchangeably, “corporation” emphasizes the entity’s legal and financial structure, which is particularly relevant in highly regulated industries like pharmaceuticals and aerospace.

Regardless of the label, the operational challenges remain the same: deliver customer-defined products on time, at scale, and within strict regulatory requirements—all with a workforce that is flexible, certified, and accountable.

What Is the Difference Between a CMO and a CDMO?

Understanding the CMO vs CDMO distinction is important. A CDMO, contract development and manufacturing organization, provides both development and manufacturing services. In contrast, a contract manufacturing organization focuses strictly on manufacturing. If you’re wondering “what is a CDMO?”. Think of it as an all-in-one partner that supports both product development and scaled production.

While the scope of work differs, both models rely heavily on agile, skilled labor to support customer-specific processes and meet tight deadlines. That makes workforce operations a central pillar of success, regardless of acronym.

The Workforce Scaling Challenge for CMOs

Contract manufacturing organizations face mounting pressure to scale quickly—without compromising quality or compliance. This is easier said than done when operations depend on people.

Key workforce challenges in a contract manufacturing organization include:

- Fluctuating Labor Demands: Staffing needs change based on contract volume, production phases, and customer deadlines.

- Compliance Risk: CMOs must track worker certifications, FDA regulations, and GMP (Good Manufacturing Practice) requirements.

- Inefficient Scheduling: Manual or siloed scheduling methods make it hard to align labor with real-time production needs.

Adding headcount doesn’t automatically solve these issues. In fact, it can compound them without a centralized, data-driven approach to workforce management.

Why Scaling Requires More Than Hiring

In a contract manufacturing organization, every contract introduces new complexity. A client may require specialized packaging, batch testing protocols, or segregated production lines, all of which have labor implications.

Here’s why simply hiring more workers falls short:

- Skill Gaps: A larger workforce is only effective if it has the right skills for the job. In GMP environments, assigning unqualified workers can lead to costly compliance issues.

- Scheduling Conflicts: Uncoordinated shifts, overlapping PTO, and last-minute absences disrupt production timelines.

- Operational Silos: Labor decisions made in isolation from production planning or MES (Manufacturing Execution System) data can result in over- or under-staffing.

34% of organizations say the biggest barrier to increasing employee productivity is skills challenges such as training, upskilling, and reskilling, especially during periods of growth. Hiring alone is no longer enough when it comes to scaling your organization. Without a comprehensive integrated system, many employees will be left behind.

Automation Enables Scalable Agility

Contract manufacturing organizations need to move quickly when onboarding new clients or scaling production for an existing one. But traditional workforce management tools are rarely designed with this level of agility in mind.

Here’s how automation helps:

- Faster Shift Filling: Automated call-off and overtime workflows reduce reliance on manual outreach or phone trees.

- Improved Labor Forecasting: Integrated labor demand planning helps anticipate future needs based on contract pipelines.

- Lower Costs: By reducing overstaffing and overtime dependency, CMOs maintain better control over labor spend—without compromising output.

Workforce automation ensures CMOs can stay flexible in volatile markets without sacrificing labor compliance or quality control. It frees up supervisors to focus on operational execution rather than administrative tasks. Over time, this leads to faster scaling, fewer bottlenecks, and stronger client satisfaction. l.

Linking Labor Operations to the Shop Floor

Modern CMOs often operate with advanced MES or ERP systems, but many still manage labor separately. This disconnect can lead to staffing errors, line delays, or missed quality checks.

When labor systems integrate with manufacturing systems, the benefits include:

- Accurate Staffing: Real-time job assignments align with actual shift presence and employee qualifications.

- Streamlined Schedule Changes: Labor availability data informs changeover schedules, minimizing idle time.

- Coordinated Decision-Making: HR, operations, and compliance teams work from the same data, improving alignment.

This end-to-end connectivity transforms labor from a back-office function to a strategic asset. It improves responsiveness during production disruptions and ensures labor plans adapt as quickly as machine processes. The result is a more agile, resilient operation capable of meeting client expectations at scale.

How Indeavor Supports Scalable Workforce Operations

At Indeavor, we understand the distinct pressures of operating a contract manufacturing organization. Whether you’re producing medical devices, personal care goods, or pharmaceuticals, your labor force must be agile, compliant, and always ready.

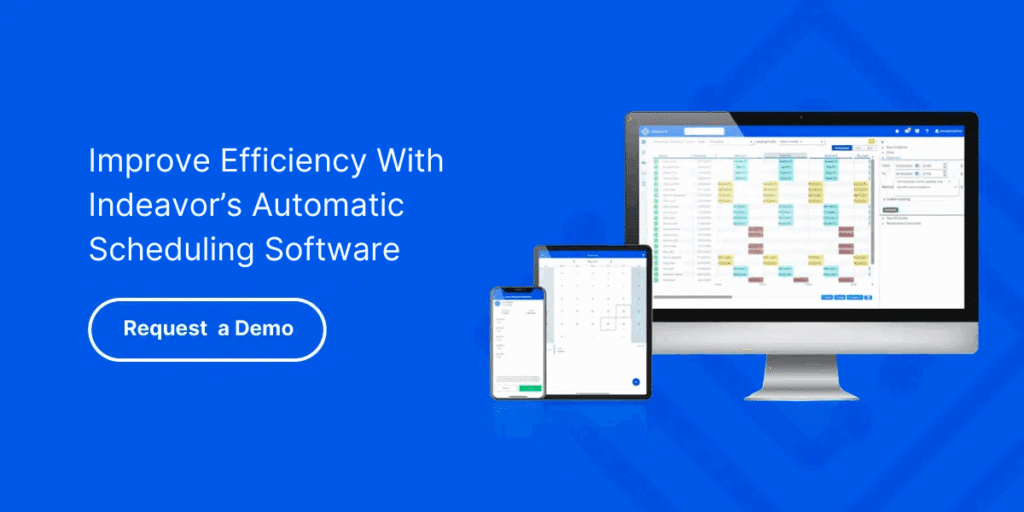

Our workforce management software helps you:

- Automated Scheduling: Eliminate manual scheduling spreadsheets with intelligent automation that fills shifts based on availability, qualifications, fatigue rules, and labor demand. In effect reducing administrative time and human error.

- Demand-Based Scheduling: Rather than setting static shift schedules, labor plans are dynamically aligned to production orders, batch timelines, and contract priorities. This minimizes downtime and ensures the right resources are available when needed.

- Competency Tracking: With built-in training and certification validation, only qualified employees are scheduled for GMP-sensitive roles. Audit trails are automated, making compliance easier and less stressful.

- Absence Management: Automated bidding, vacation planning, and real-time absence tracking help CMOs avoid unexpected labor shortages while improving employee satisfaction.

- Compliance Tracking: Ensure regulatory readiness with real-time tracking of worker certifications, union rules, and hours worked. Easily generate documentation to support internal audits and FDA inspections.

Contract manufacturing organizations are poised for rapid growth, but only if their labor operations can keep pace. With the right strategy and tools in place, scaling doesn’t have to be a risk. It can be a competitive advantage.

Ready to optimize your contract manufacturing organization? Schedule a demo to learn more about how Indeavor helps CMOs meet demand, reduce risk, and scale smarter.

About the Author

Claire Pieper is the Digital Marketing Specialist for Indeavor. In her role, she specializes in crafting strategic and engaging content, ensuring that customers are well-informed. Claire is dedicated to enhancing the customer experience and optimizing the user journey through Indeavor’s solutions. To learn more or get in touch, connect with Claire on LinkedIn.